How to Use a Multi-Function Power Meter to Save Your Business from Unseen Electricity Costs?

Unseen Electricity Bills Are a Business’s Biggest “Hidden Expense”

Businesses often face frustratingly high electricity bills, but where exactly is the cost coming? Traditional power meters can only provide a simple total consumption number, offering no insight into specific usage patterns or energy quality. This lack of data prevents companies from identifying where their biggest inefficiencies lie. The multi-function power meter is the key to unlocking the secret of these "unseen electricity costs." This article will explore how a single device can revolutionize your energy management, from data monitoring to fault early warning, and help you find hidden savings.

Beyond the Old Way: Why It's Time to Upgrade to a Multi-Function Power Meter

The Limitations of Traditional Meters

Traditional power meters are limited to simple measurement and billing. They cannot analyze energy consumption by time, monitor specific equipment usage, or assess power quality issues. Without this crucial data, businesses are essentially operating in the dark, unable to make informed decisions to optimize their energy use. It's like driving a car without a dashboard—you know you're moving, but you have no idea how fast you're going or if your engine is healthy. For too long, companies have been paying for electricity with no clear understanding of their usage patterns. This leaves them vulnerable to unexpected costs from power surges, reactive power, and harmonic distortions, which are never itemized on a standard utility bill. These invisible inefficiencies accumulate over time, turning a seemingly manageable expense into a significant financial drain. The inability to correlate specific operational activities with energy consumption makes it nearly impossible to implement effective energy-saving measures or justify investments in more efficient equipment.

The Value of a Multi-Function Power Meter

In comparison, a multi-function power meter is not just a measuring device; it’s a powerful analytical tool. It provides a comprehensive view of your electrical system, giving you the detailed information you need to make smart, cost-saving decisions.

- It helps you understand not just how much power you're using, but how you're using it, where you're using it, and when you're using it. This detailed data is the foundation of any effective energy management strategy.

- It uncovers inefficiencies and pinpoint energy-wasting equipment by providing granular data on individual circuits, machines, or departments. This allows you to prioritize maintenance and upgrades where they will have the greatest impact on your bottom line.

- It is essential for ensuring the stability and quality of your power supply, which directly impacts the lifespan and performance of your electrical equipment. By monitoring for power quality issues, you can prevent costly damage and production downtime.

To highlight these differences, let's look at a comparison between a multi-function power meter vs traditional meter.

| Features | Traditional Meter | Multi-Function Power Meter |

| Data Provided | Total kilowatt-hour (kWh) consumption | Real-time voltage, current, power, power factor, frequency, and energy consumption |

| Analytical Capability | None | Detailed analysis of energy usage trends, harmonic content, and load curves |

| Functionality | Basic measurement for billing | Energy monitoring, power quality analysis, fault alarming, and remote control |

| Problem Identification | Ineffective at identifying root causes of high bills | Pinpoints specific power quality issues like harmonics and voltage sags |

Data Is King: How to Use a Multi-Function Power Meter for Precise Energy Management

Real-Time Monitoring and Data Visualization

A multi-function power meter offers the ability to collect and display real-time data, including voltage, current, and power factor. This data is often presented through intuitive charts and dashboards, allowing you to visualize your energy consumption patterns. This gives you the power to find specific energy "black holes" within your business. For instance, you might discover that a particular production line or HVAC system consumes a disproportionate amount of power during off-peak hours. The visualization capabilities go far beyond a simple chart; they can provide detailed load profiles, showing power demand throughout the day, week, or even month. This insight allows you to identify specific periods of peak demand, enabling you to shift loads or schedule operations to take advantage of off-peak electricity rates, resulting in significant savings. Furthermore, these meters can track both active and reactive power, giving you a complete picture of your energy usage and helping you determine if a poor power factor is contributing to higher bills.

Harmonic Management: Stop Paying for "Wasted Energy"

Harmonics are electrical distortions that don't contribute to useful work but still consume energy, generating "wasted energy" costs. The multi-function power meter can identify harmonic content and its impact on your system. This allows you to take corrective action, such as installing harmonic filters, to improve power quality, reduce energy loss, and save money. Harmonics are primarily caused by non-linear loads common in modern facilities, such as variable speed drives, LED lighting, and server power supplies. These distortions can lead to equipment overheating, circuit breaker nuisance tripping, and inaccurate measurements. By using a multi-function power meter, you can monitor these distortions and generate reports that quantify the problem. This data is invaluable for justifying the cost of harmonic mitigation equipment, as it provides a clear ROI in terms of reduced energy loss and improved equipment reliability.

- They help you identify and address harmonic issues by providing a clear view of harmonic distortion levels on your electrical system.

- They lead to improved power quality, which in turn reduces stress on electrical equipment and prevents premature failure.

- They reduce unnecessary energy consumption and costs by eliminating the wasted energy associated with harmonic distortions.

Prevention Is Better Than Cure: Your Multi-Function Power Meter as an "Electrical Doctor"

Fault Early Warning and Troubleshooting

Downtime due to electrical faults can be extremely costly, with every minute of a production shutdown potentially costing thousands of dollars. A multi-function power meter acts as an early warning system. By constantly monitoring key parameters, it can detect anomalies such as overcurrents, over- and undervoltages, or phase imbalance. When a parameter exceeds a set threshold, the device issues an immediate alarm. This allows your team to investigate and resolve issues before they escalate into major failures. This is a critical function for effective multi-function power meter troubleshooting. Beyond real-time alerts, the meter also logs historical data, capturing a precise record of the event. This data is invaluable for a root cause analysis, allowing engineers to review conditions leading up to the fault. For example, by analyzing the data log, a team might discover that a sudden voltage sag always precedes a motor trip, indicating a specific issue with a feeder line. This proactive approach saves time and money that would otherwise be spent on reactive, emergency repairs.

- It provides timely warnings for electrical anomalies, helping to prevent catastrophic equipment failures and safety hazards.

- It enables rapid diagnosis and resolution of issues by providing detailed data logs that pinpoint the exact moment and nature of a fault.

- It minimizes expensive downtime, ensuring operational continuity and protecting your bottom line from unexpected interruptions.

Optimizing Equipment Efficiency and Lifespan

The power factor is a measure of how effectively electrical power is being converted into useful work. A poor power factor can lead to higher electricity bills and fines from utilities who often penalize customers with a low power factor. A multi-function power meter allows you to monitor and optimize your power factor, ensuring you're only paying for the power you actually use. By continuously monitoring the power factor, you can determine if you need to install power factor correction capacitors. The savings from avoiding utility penalties alone can often pay for the meter in a very short amount of time. Moreover, a stable power supply free from fluctuations and harmonics, which the meter can help you maintain, extends the lifespan of your equipment, reducing maintenance and replacement costs. For sensitive electronics, a clean power supply is essential to prevent damage to internal components. For motors and other inductive loads, a good power factor improves efficiency and reduces heat, leading to longer service life and less wear and tear.

Selection and Implementation: Choosing the Right Multi-Function Power Meter for Your Business

How to Choose the Right Model

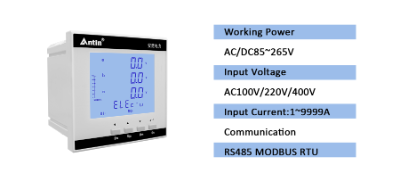

Selecting the right meter depends on your specific needs. It's not about finding the most expensive model, but the one that offers the best value for your requirements. When considering a multi-function power meter price list, you should evaluate factors like the meter’s accuracy class, communication protocols, and specific functions such as harmonic analysis. You should start by defining your goals: Are you just looking to monitor total energy consumption, or do you need to perform detailed power quality analysis for a critical machine? The answers to these questions will guide your selection. Also consider the communication capabilities you need. Do you require a simple Modbus RTU connection to a local display, or do you need Ethernet/IP connectivity to integrate with a plant-wide SCADA system?

Installation and Deployment

Proper installation is paramount to ensuring your meter operates effectively. While the process may seem straightforward, it’s crucial to follow the manufacturer’s guidelines. By referring to the multi-function power meter wiring diagram, you can ensure the device is correctly integrated into your electrical system. A common pitfall is incorrect current transformer (CT) orientation, which can lead to negative power readings and inaccurate data. This is why we highly recommend consulting with a professional electrician to ensure a safe and correct installation. Furthermore, proper sensor placement is vital for accurate readings. The meter must be installed on the circuit or device you intend to monitor, and all connections must be secure and free from interference to ensure data integrity.

For Specific Industries

Different industries have different needs. For example, a multi-function power meter for solar system must be capable of bidirectional energy measurement to accurately monitor both consumption from and injection to the grid. The same applies to other specific applications. In manufacturing, you might use meters to monitor the efficiency of individual motors and machinery to identify maintenance needs. In a data center, meters can be installed at the rack or PDU level to track energy usage and optimize cooling. In commercial buildings, they can be used for tenant sub-metering, accurately allocating energy costs to different departments or lessees. By choosing a meter designed for your specific application, you can gain deeper insights and achieve greater savings.

From Investment to Return, The Long-Term Value of a Multi-Function Power Meter

A multi-function power meter is not just a one-time purchase; it is a long-term investment that provides a return by transforming how your business manages energy. By moving beyond simple metering to data-driven decision-making, you can uncover hidden savings, improve operational efficiency, and lay the foundation for a smarter, more sustainable future for your business. The ability to monitor, analyze, and troubleshoot your electrical system proactively ensures that your business can thrive without being burdened by unseen electricity costs. The data from a multi-function power meter is not just numbers; it's a powerful tool for a more efficient and profitable future.